Zero Training Required: Operators of any skill level can run it efficiently.

YOUR CONVERSION COST IS X%. BOXMAKER IS 4%. WHAT'S YOUR PLAN?

The future of Indian corrugation is here. Are you ready to claim it?

Fully Automatic and Single Pass Operations. Supports 100+ Corrugated Box Types. Most Cost effective Corrugated Box Making Machine. Multiple functions – Slotting, Scoring, Slitting, Trimming and Die-cutting, Inline Gluing.

Advance corrugated box making machine BT2000 & BT2500

Meet the Machines Changing the Game:

BT1800, BT2000 & BT2500

Discover the next generation of corrugated box making with our advanced machines.

BT1800

BT1800: The Economical Box Maker Machine

- BT1800: The Economical Leader

- Maximum output for medium scale operations.

- Boards up to 1800mm.

- Designed for peak efficiency and productivity.

- From ₹32 lakhs + GST

BT2000

BT2000: The Ultimate Multifunctional Box Maker Machine

- BT2000: The Versatility Powerhouse

- Produce 100+ box styles on demand.

- Boards up to 2000mm.

- Ideal for diverse, high-margin short runs.

- From ₹42 lakhs + GST

BT2500

BT2500: The Heavy Duty Powerhouse Box Maker Machine

- BT2500: The High-Capacity Leader

- Maximum output for larger scale operations.

- Boards up to 2500mm, 7 ply, 16 mm

- Designed for peak efficiency and productivity.

- From ₹89 lakhs + GST

The Core Problem & Solution

Stop Fighting the Box Business. Start Profiting From It.

IS YOUR BUSINESS SELLING KILOS , OR EARNING RUPEES?

The low-margin fight ends here. BOXMAKER transforms you from a commodity supplier to a high-value packaging partner.

WHO OWNS YOUR PLANT? YOU, OR YOUR OPERATOR?

Take back control. Our automation slashes manpower by up to 70%, ending operator dependency and putting you in charge.

IS LACK OF SPACE IN YOUR PLANT IMPACTING BUSINESS?

Maximize your footprint. One BOXMAKER replaces multiple old machines, freeing up valuable space for growth and higher output.

YOUR CONVERSION COST IS X%. BOXMAKER IS 4%. WHAT'S YOUR PLAN?

Convert challenges into profit. Drastically cut costs on every box with BOXMAKER’s ultra-efficient, automated process.

YOUR NEIGHBOR BOUGHT THIS MACHINE. WHAT'S YOUR PLAN?

Stay ahead. BOXMAKER is your competitive edge, enabling you to capture the profitable jobs your rivals can’t touch.

IMPORTED MACHINE? IMPORTED PROBLEMS.

Trust local. BOXMAKER is built and serviced in India, by people who speak your language and understand your business. No more international delays.

The BOXMAKER.TECH Advantage

The BOXMAKER.TECH Difference: Why Choose Us?

Our Commitment

Your Partner in Profitability

Supports 100+ Box Styles

Most Cost-effective Carton Box Making

Fully Automatic And Single Pass

all in one compact solution

Customizable Solutions

Boxmaker is more than just a machine – it's a proven investment

At BOXMAKER.TECH, we engineer solutions for the real challenges of the Indian corrugation industry. We believe in making efficiency effortless, profitability accessible, and support local. Join us to transform your operations and secure your future.

Functions

BOXMAKER Functions

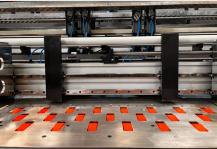

CARDBOARD FEEDING

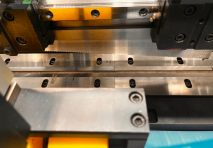

HORIZONTAL SLOTTING & SCORING

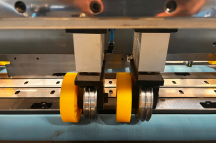

VERTICAL CREASING

VERTICAL SLITTING

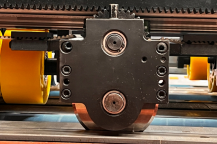

HORIZONTAL CUTTING

DIE-CUTTING

Your Competitor bought this machine. What's your plan?

Stay ahead. BOXMAKER is your competitive edge, enabling you to capture the profitable jobs your rivals can’t touch.

Not Only Deliver Corrugated Boxes Machinery But Also Deliver Service